Difference Between Feed Pellet Machine And Wood Pellet Machine

Are you interested in delving into the fascinating world of pellet machines? Look no further! In this comprehensive article, we will explore the key differences between feed pellet machines and wood pellet machines. These two types of equipment play vital roles in distinct industries, each serving a unique purpose.

Whether you’re involved in animal feed production, pet food industry, wood processing companies, power plants, or heating projects, understanding the dissimilarities between these machines is essential.

So, what exactly sets feed pellet machines and wood pellet machines apart? Let’s find out. We’ll examine various aspects, including the raw materials they utilize, the specifications of the pellets they produce, their design and structure, production capacities, and the diverse applications they cater to.

By the end of this article, you’ll have a clear understanding of these machines and their respective uses, empowering you to make informed decisions for your specific needs.

Throughout this journey, we’ll adopt an analytical perspective while maintaining an engaging and conversational tone. By incorporating real-life examples and taking a storytelling approach, we’ll make sure the content remains punchy and easy to understand. So, buckle up, and let’s explore the intriguing world of feed pellet machines and wood pellet machines.

But first, let’s introduce these two types of pellet machines briefly.

Feed Pellet Machine and Wood Pellet Machine

Feed pellet machines and wood pellet machines are specialized equipment used in different industries to process raw materials into compact and uniform pellets. Let’s explore their definitions and defining characteristics in more detail:

Feed Pellet Machine:

Feed pellet machines are designed specifically for the production of animal feed pellets. They are widely used in the animal feed production and pet food industry.

These machines take various grains, crop byproducts, and other agricultural materials as raw materials and transform them into nutritionally balanced feed pellets. The pellets produced by feed pellet machines are formulated to meet the specific dietary requirements of different animals, ensuring their proper growth, health, and overall well-being.

The defining characteristics of feed pellet machines include their ability to process a wide range of raw materials such as corn, wheat, soybean meal, and more.

These machines offer flexibility in adjusting the pellet size, typically ranging from 2 to 12 millimeters, to suit the needs of different animals and feeding methods. Feed pellet machines are designed with a simple structure, making them user-friendly and easy to operate. They focus primarily on the pelletizing process without incorporating additional systems like drying or cooling.

Wood Pellet Machine:

Wood pellet machines are specialized equipment used in the wood processing industry to convert wood chips, branches, sawdust, and other wood waste into dense and compact wood pellets.

These pellets serve as a renewable source of energy and are widely used as biomass fuel in stoves, boilers, and biomass power plants.

Wood pellet machines have defining characteristics that set them apart. Unlike feed pellet machines, wood pellet machines incorporate additional systems such as drying, granulation, and cooling to ensure the production of high-quality wood pellets.

They require pre-processing of raw materials, including drying the wood chips or sawdust to the appropriate moisture level before pelletization. Wood pellet machines produce pellets with a standardized diameter of 6 to 12 millimeters to ensure compatibility with various combustion devices. These machines generally have higher production capacities, ranging from 1 to 2 tons per hour for medium-sized machines, due to the denser nature of wood materials.

Understanding the defining characteristics of feed pellet machines and wood pellet machines is crucial for businesses in the animal feed production, pet food industry, wood processing companies, power plants, or heating projects. This knowledge enables them to choose the appropriate machine that aligns with their specific requirements and ensures efficient and high-quality pellet production.

Feed pellet machines and wood pellet machines are two distinct types of pelletizing equipment that serve different purposes. Understanding the difference between them is crucial for individuals or businesses involved in animal feed production, pet food industry, wood processing companies, power plants, or heating projects.

Now let’s delve into the dissimilarities between feed pellet machines and wood pellet machines, examining their raw materials, pellet specifications, design and structure, production capacity, application scope, and more. By the end of this article, you will have a comprehensive understanding of these two machines and their respective applications.

Pellets Business Ideas:

Pellet Production Profit Analysis: Is it a Profitable Business?

Raw Materials

A. Feed pellet machine

Feed pellet machine processes grains and crop byproducts into feed pellets[1]. These machines are designed to convert various agricultural raw materials such as corn, wheat, barley, soybean meal, and other grain and crop byproducts into nutritious feed pellets.

The processed feed pellets are formulated to meet the specific nutritional needs of different animals, including poultry, livestock, and pets.

B. Wood pellet machine

It uses wood chips, branches, and wood waste to make wood pellets. Unlike feed pellet machines, wood pellet machines are primarily used in the wood processing industry. They transform raw materials like wood chips, sawdust, bark, and other wood residues into dense and compact wood pellets.

These pellets serve as a renewable source of energy and are used in stoves, boilers, and biomass power plants.

How to Tutorial:

Pellet Specifications

A. Feed pellets:

2-12 mm, suitable for different animals[2]. Feed pellet machines produce pellets in a range of sizes, typically between 2 to 12 millimeters. The size of the feed pellets is determined based on the target animal’s requirements and the feeding method employed.

Different animals have varying pellet size preferences, and the feed pellet machine allows for customization to meet those needs.

B. Wood pellets:

6-12 mm, used in stoves, boilers, and biomass power plants. Wood pellet machines, on the other hand, produce wood pellets with a diameter ranging from 6 to 12 millimeters.

This standardized size ensures compatibility with various wood pellet combustion devices, such as residential stoves, industrial boilers, and biomass power plants.

Design and Structure

A. Feed pellet machine:

Simple design for single use and is easy to operate. Feed pellet machines feature a relatively simple design, typically intended for single-use applications.

They are user-friendly and easy to operate, making them suitable for small to medium-scale animal feed production. These machines focus on the pelletizing process, without incorporating additional systems.

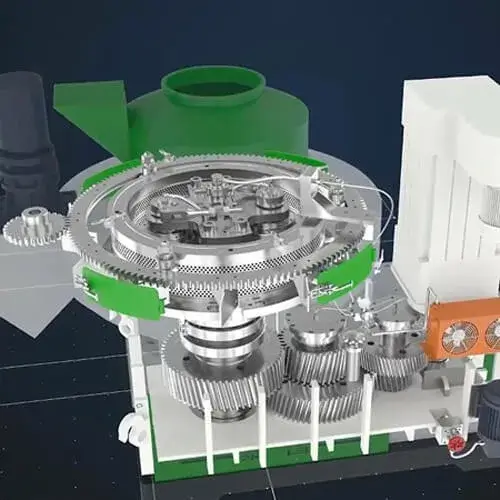

B. Wood pellet machine:

Incorporates drying, granulation, and cooling systems, and is more complex. Wood pellet machines are more complex in design compared to feed pellet machines.

They incorporate multiple systems, including drying, granulation, and cooling. This comprehensive approach ensures the production of high-quality wood pellets with optimal moisture content and temperature[3].

Furthermore, wood pellet machines require pre-processing of raw materials, such as drying the wood chips or sawdust to the appropriate moisture level before pelletization.

Wood pellet machine has higher requirements on raw materials and it needs pre-processing. Due to the complexity of wood pellet machines, they have higher requirements for raw materials compared to feed pellet machines.

Wood materials used for pellet production need to be free from contaminants, have consistent moisture content, and undergo pre-processing steps to ensure the quality and efficiency of the pelletization process.

Production Capacity

A. Wood pellet machine:

Wood pellet machine generally has higher capacity, 1-2 tons/hour for medium-sized machine.

Wood pellet machines are known for their higher production capacity compared to feed pellet machines. A medium-sized wood pellet machine is capable of producing around 1 to 2 tons of wood pellets per hour.

This higher capacity is due to the denser nature of wood materials, which allows for more efficient pellet production.

B. Feed pellet machine:

The feed pellet machine has a lower capacity due to less dense raw materials.

In contrast, feed pellet machines have lower production capacities compared to wood pellet machines. The raw materials used for animal feed production, such as grains and crop byproducts, are less dense and require more processing to form pellets.

As a result, the production rate of feed pellet machines is typically lower.

C. Production capacity depends on raw material type, machine size, and power. It’s important to note that the production capacity of both feed pellet machines and wood pellet machines can vary depending on various factors.

The type and quality of raw materials, the size and power of the machine, and the specific settings and adjustments made during operation all play a role in determining the overall production capacity[4].

Application Scope

A. Feed pellet machine:

Feed pellet machine mainly used in animal feed production and pet food industry.

Feed pellet machines find their primary application in the animal feed production and pet food industry. These machines enable the conversion of various agricultural byproducts into nutritionally balanced feed pellets, meeting the dietary requirements of different animals.

The feed pellets produced are used to feed poultry, livestock, and pets, ensuring their proper growth and health.

B. Wood pellet machine:

Wood pellet machine suitable for wood processing companies, power plants, heating projects to produce wood pellet fuel.

Wood pellet machines have a broader application scope. They are essential in wood processing companies, where they transform wood waste and byproducts into valuable wood pellets for fuel purposes.

Wood pellets are also used in power plants and heating projects as a renewable and eco-friendly alternative to fossil fuels, contributing to sustainable energy production.

C. End products used for different purposes: (Animal feed vs. biomass fuel).

The key distinction between the applications of feed pellet machines and wood pellet machines lies in the end products they generate. Feed pellet machines produce feed pellets specifically formulated for animal consumption.

These pellets provide the necessary nutrients for animals’ growth, development, and overall well-being. On the other hand, wood pellet machines produce biomass fuel in the form of wood pellets, serving as a clean and efficient energy source for various industries and residential heating systems.

How to Tutorial:

10 Common Pellet Maker Problems and How to Fix Them

Conclusion

In conclusion, the difference between feed pellet machines and wood pellet machines is significant in terms of their raw materials, pellet specifications, design and structure, production capacity, and application scope.

Understanding these distinctions is crucial for businesses involved in animal feed production, pet food industry, wood processing companies, power plants, or heating projects.

In this article, we have explored the key differences between feed pellet machines and wood pellet machines.

Let’s summarize the main points we’ve covered:

● Feed pellet machines are designed for the production of animal feed pellets, using grains and crop byproducts as raw materials. Wood pellet machines, on the other hand, process wood chips, branches, and wood waste to produce wood pellets used as biomass fuel.

● Feed pellets have sizes ranging from 2 to 12 millimeters, tailored to meet the nutritional needs of different animals. Wood pellets, on the other hand, have a standardized diameter of 6 to 12 millimeters to ensure compatibility with various combustion devices.

● Feed pellet machines have a simple design and are easy to operate, while wood pellet machines incorporate additional systems like drying, granulation, and cooling, making them more complex.

● Wood pellet machines generally have higher production capacities, ranging from 1 to 2 tons per hour for medium-sized machines, due to the denser nature of wood materials. Feed pellet machines have lower capacities due to the less dense raw materials they process.

● The applications of feed pellet machines are primarily in the animal feed production and pet food industry, providing nutritionally balanced feed for different animals. Wood pellet machines are used in wood processing companies, power plants, and heating projects to produce biomass fuel.

To explore and find suitable pellet machines for your specific needs, we recommend visiting TCPel’s website, a B2B pellet machine company.

TCPEL offers high-quality pellet machines designed to meet diverse requirements in the industry. You can find more information about their pellet machines here and specifically about feed pellet machines here.

With the knowledge gained from this article, you can make informed decisions when it comes to choosing the right pellet machine for your business needs, whether it’s in the animal feed production industry or the wood processing and biomass fuel sector.

Remember, selecting the appropriate pellet machine is crucial for efficient and high-quality pellet production.

To explore further and find suitable pellet machines for your specific needs, consider visiting TCPel’s website. TCPel offers a range of high-quality pellet machines designed to meet diverse requirements in the industry.

Talk to An Expert

SHARE THIS POST

Talk to An Expert