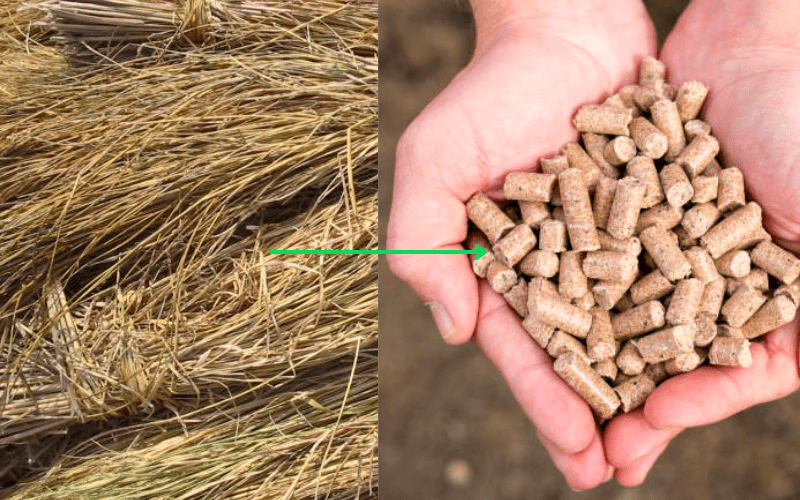

How to Make Straw Pellets in 2023?

Straw is basically the residue left from harvesting plants like wheat, rice, corn, etc. It is one of the most common agricultural residues produced from various agricultural processes. It is also the most important agricultural residue in various countries.

In fact, around 23 million tons of straw are produced each year which can be used in multiple industries for various processes.

Now the question that arises is how exactly the straw is actually used for various purposes. Well, the straw is converted to pellets of high quality and then they are used as per requirements. The straw pellets are mainly made using pellet-making machines which are available in different varieties.

So, you can pick your right choice of pellet-making machine and use it for preparing large quantities of straw pellets for multiple purposes.

You can also use the TCPEL pellet-making machine if you are willing to produce the best quality straw pellets in a smooth and effective manner.

Applications Of Straw Pellets

Straw pellets are used for multiple purposes in our day-to-day lives. Some of the major applications of straw pellets have been mentioned below:

Using straw pellets as fuel:

Straw pellets are quite frequently used as fuel for various household purposes. They are a substitute for traditional fuels. The pellets are not only eco-friendly but they are also renewable.

So, you can use them as fuel oil without causing any kind of harm to the environment. Nowadays, a lot of factories and other commercial plants are also using straw pellets as their source of fuel.

Using straw pellets as animal feed:

Straw pellets are considered to be really good fodder for animals like. These straw pellets can provide the animals with balanced nutrition.

They are also quite easy to store. The pellets can be stored for years without any kind of inconvenience at all. The nutritional value of the pellets can also be altered as per your exact requirements.

Using straw pellets as animal bedding:

Besides using straw pellets for animal fodder, you can also use them as animal bedding. Straw pellets are a popular choice of animal bedding because of their low costs. These pellets are also made up of natural material only.

So, they do not cause any kind of harm to the animals. The straw pellets are also available in abundant quality which again makes them perfect for animal bedding.

Pellet Machines Needed for Straw Pellets

If you want your straw pellet-making process to be a smooth and streamlined one, then it is important that you invest in the right pellet-making machine for yourself.

This will help you out in getting the maximum outcome from your business efforts. Here are a few things that you need to consider while investing in a pellet machine:

Consider the type of pellet machine:

There are two main types of pellet machines available that can be used for straw pellet production:

Flat die pellet machines: Flat die pellet machines are a compact and affordable option for making pellets. They are mainly suitable for small-scale business operations. These pellet machines compress the straw between the two flat dies. They are quite easy to operate and are also suitable for beginners who are just starting off with their businesses.

Ring die pellet machines: Ring die pellet machines are larger. They are most used for large-scale industrial operations. These machines use shift die and rollers to compress the straw into pellets. They are of higher capacity as compared to flat die pellet machines and can produce pellets of consistent density and size.

Consider the available features:

The next thing that you need to consider is the available features. Different pellet machines have different features.

So, this is something that you are required to consider. Some of the key features of the pellet-making machines have been listed below:

Capacity: It is really important for you to pick the pellet machine of the right capacity. This will help you in ensuring that your business needs are fulfilled. You should also carefully assess your exact capacity requirements before investing in the right pellet machine.

Power source: Next, you need to consider the power source. Different pellet machines are powered by different power sources like diesel, electricity, etc. So, choose a power source that aligns with your available resources, and then pick the right machine for yourself.

Maintenance: The next point of consideration is the maintenance. You would not want to invest in a pellet-making machine that requires frequent maintenance. Instead, always go for a machine that is highly durable and does not require you to opt for frequent maintenance activities from time to time.

Pellet size: You must also consider the pellet size while investing in your pellet-making machine. Different pellet machines produce pellets of different sizes. So, this is again something that needs to be put into consideration. Some pellet machines also allow you to customize the size of the pellets.

Budget: Budgetary constraints are always crucial. You may have the best features in your pellet-making machine but for that, you need to invest a huge sum of money and you may not be prepared for that. So, always consider the budget and then pick the right machine for yourself. This is going to help you in carrying out your business operations in a streamlined manner.

How To Make Straw Pellets?

Given below are the crucial steps to make straw pellets:

Preparing the raw material: The first step would be to prepare the raw materials. Straw contains a high amount of dust which can affect the quality of the straw pellets being produced. So, it is really important for you to carefully screen the raw materials for any kind of contaminants that can interfere with the pellet quality. Materials like stones, metals, and rocks are removed before the raw materials are further processed.

Grinding: The straw biomass is a pipe-like material that has a diameter of around 4 to 8 mm and a thickness of around 0.3 to 0.6mm. In order to produce the straw pellets from raw materials, it is important for you to grind the raw materials to get the particles of desired size. Grinding of straws also involves cutting and chopping the straw into small particles so that the pellets can be produced conveniently.

Drying: The straw may contain a high amount of moisture. In fact, there is around 15% moisture in straw. The moisture content is not at all good for high-quality pellet production. So, it again becomes important for you to process the raw material so that the straws can be produced to perfection. Different types of drying machines are used to extract the moisture content from the straw. The drying is done till most of the moisture content is removed.

Conditioning: Straw requires special conditioning so that the desired amount of hardness can be achieved. Conditioning involves the application of water or steam at high temperatures and the addition of different kinds of binding agents so that straw particles are not very loose. Conditioning is mainly done to achieve the necessary moisture and temperature levels. It also helps in increasing the malleability of the straw. The binding agents are mainly used to increase the strength of the raw material. It also reduces the chances of abrasion during the pelletizing process.

Pelletizing: During pelletizing, it is really important for you to keep various important factors under consideration like particle size, density, fiber strength, moisture content, etc. You must be careful about the kind of binding agent you are using for preparing the straw pellets as it is directly going to affect the quality of the pellets. You must also choose the best quality pellet-making machine for producing straw pellets. Always reach out to a reputed manufacturer only while buying your pellet-making machine. Also, ensure that the pellet particles are of the best possible quality.

Cooling and screening: The newly produced straw pellets are hot and soft. These pellets need to be cooled down to the desired temperature so that they acquire the required hardness. Once the straw pellets are cooled, it is time to screen them to remove the residue. You must also be careful about storage. Make sure that the place where you are storing the straw pellets is cool and dry. This is going to ensure that the quality of the pellets is maintained.

Taking the safety measures: There are a lot of problems that you might encounter during the pellet-producing process. This involves pellet breakage, overheating, high energy consumption, reduced pellet quality, and high maintenance of the pellet mills. All these problems can be avoided by investing in the best quality pellet-making machine that has all the necessary safety measures installed in it.

How to Build A Complete Straw Pellet Plant?

Here’s how you can build a complete straw pellet plant:

Feasibility study: The first step towards building a complete straw pellet plant is a feasibility study. You need to understand how feasible it is for you to get into the pallet manufacturing business. You must also conduct research on the target market analyze the availability of raw materials and check the other competitors in the industry. This is indeed going to provide you with a kickstart and you are going to be able to acquire an edge in the competitive world.

Business plan: No business becomes successful without a proper business plan. So, it again becomes really inevitable for you to create a proper business plan for your straw pellet manufacturing business. The business plan should have all your business goals and objectives listed down carefully. You should also consider the budget, the available financial options, and the marketing strategy. This is going to help you out in executing your plan successfully. You are also going to acquire a kickstart in this competitive world.

Raw material supply: Now here is the next thing that you need to consider. It is really important for you to look for a consistent supply of raw material which is straw. You may also get in touch with straw suppliers and local farmers. This will ensure that your business is up and running. You will also not have to disrupt your business operation simply because of a shortage of raw materials. Also, make sure that the raw material that you are using is of the best quality. Only then will the straw pellets produced be of the best possible quality.

Site selection: The next job is site selection. It is important that you select a proper site for your pellet plant. Make sure that the site is close to raw material sources. It should also be well connected by roadways so that you can transport your goods to different locations. The environmental factor should also be considered while you are choosing your location for the pellet plant. It is also essential for you to obtain certain permits for the site before you actually start off with your business.

Design and layout: Now you need to create a detailed design and layout for your pellet production factory. You may take the help of a professional as well for designing the layout. The design should include the placement of the machinery, the workplace layout, the storage area, etc. Also, make sure that the pellet plant is designed in such a way that it increases efficiency and productivity.

Equipment installation: The final step is to install the necessary equipment at desired locations in your pellet factory. You should also have all the safety equipment installed at careful locations so that all your business operations can be carried out in a smooth and convenient manner without you having to undergo any kind of trouble at all.

Conclusion

And this is how you can prepare high-quality straw pellets in a quick and convenient way.

Also, if you are willing to invest in the best quality pellet making for producing straw pellets, then you may get in touch with TCPEL and produce the best quality straw pellets as per your business needs.

Talk to An Expert

SHARE THIS POST

Talk to An Expert