How to make feed pellets with a Flat Die Pellet Mill?

Are you aware of the concept of feed pellets? If not, then let me tell you that you have indeed landed at the right place.

Feed pellets have a big role to play in offering the animals the desired nutrition. These pellets can withstand different handling conditions without undergoing any breakage or wastage. The feed pellets are also a part of the multiple industries where animals are involved. They are also quite compact and easy to store. The transportation can also be done conveniently.

The feed pellet is produced from different types of raw materials like agricultural residue and other biological forest waste. These raw materials are fed to the pellet-making machine so that the pellets of the desired size can be produced.

So, here, in this article, we are going to discuss the importance of feed pellets. We will also talk to you about how you can manufacture food pellets using the flat die pellet machine.

What is a feed pellet?

Feed pellets are nothing but pellets that are used as feed for animals. These feed pellets have high nutritional value. The nutrients present in these feed pellets can also be adjusted easily depending on the kind of raw material used in the feed pellet production process.

The feed pellets are also quite easy to prepare. They are made using pellet machines. The pellet machines allow you to have complete control over the pellet production process. They can also determine the size of the feed pellets.

The feed pellets are produced through a series of steps.

First, the raw materials are acquired for the manufacturing process. The raw materials are then processed and fed to the pellet-making machines to produce pellets of high quality.

These feed pellets serve as highly nutritional food for animals including poultry, pets, and livestock. The feed pellets also have numerous applications other than feeding livestock and poultry. You can use animal feed as a part of the shrimp and fish farming process.

They can reduce the chances of diseases in cattle because of their reduced chances of contamination. The feed pellets can also reduce environmental impact to a considerable extent.

So, you can see, that feed pellets have a big role to play in the modern animal agriculture industry. However, you must follow sustainable practices only while producing the feed. Only then will you be able to get the maximum outcome from your effort?

You should also make it a point to use the appropriate machinery for your pellet-making process. This is going to help you in preparing high-quality pellets and your business needs will be fulfilled.

How to make feed pellets for animals?

The process of making feed pellets for animals isn’t a simple one. In fact, there are quite a number of steps you need to go through in order to produce high-quality feed pellets for animals.

The steps have been mentioned for your consideration:

Acquiring raw materials: The first step is to acquire the necessary raw materials for preparing animal feed. There are different types of raw materials that can be used for pellet production. The most commonly used raw materials are rice, beans, grass, wheat, etc in most cases, larger-sized raw materials are pulverized by using hammer mills so that the sizes are consistent.

The raw materials are then fed to the pellet-making machine for pellet production. Sometimes, proteins and other nutrients are also added to the raw materials in order to increase their nutritional value.

Preparing the raw materials: Simply acquiring raw materials is not enough. It is also quite important for you to prepare the raw materials so that it can be used properly for industrial purposes. Preparing the raw materials involves crushing the material into a powdery substance. This is done using feed hammer mills.

The materials will also have to be mixed consistently using a feed mixing machine. This will ensure that the end products produced are of the best possible quality. They can also be fed to the pelletizing machine without any inconvenience at all.

Pelletizing: During this process, the actual pellets are produced. The step also involves material modulation and physical condition control. The raw materials are exposed to high heat and pressure in order to bring about modulation in their size and consistency.

The diameter of the pellet machine will also determine the quality of the pellets that you wish to produce. The pelletizing process also determines the hardness of the pellets being produced.

So, it is really important for you to choose the right kind of pellet-making machine for the manufacturing process.

Yes, you will find a lot of different pellet-making machines available in the market but all these machines are not of the exact same quality.

So, it is again important that you do your research well and pick one such pellet-making machine that will help you to produce quality feed pellets at a reduced power consumption rate. You must also consider the reputation of the pellet machine supplier and then make your choice accordingly.

It is also necessary for you to adjust the settings of the pellet-making machine before you actually start producing your pellets. The default settings might not be enough to fulfil your exact requirements. So, you should make the necessary changes to the settings and then use the device as per your exact business needs.

You can also opt for the TCPEL pellet-making machine if you are looking for endless customization capabilities in your pellet-making machine.

Cooling the feed pellets: The next step is to cool down the pellets. The pellets produced by the pellet-making machine have got a very high temperature and are not perfect for regular use. So, it is important that you naturally cool down the pellets and use them for multiple purposes.

Nowadays, a lot of different pellet cooling machines are also available in the market. These pellet coolers can be used to bring down the temperature of the pellets to normal room temperature. This again helps you in making maximum use of the pellets.

Storage and distribution: You need to find a cool and dry place for storing the pellets. Make sure that the place is free from moisture content. Otherwise, the moisture may interfere with the peller particles and their shelf life is going to reduce drastically. You can also keep the pellets away from the direct rays of the sun and get them distributed when required.

The distribution can be done easily in trucks and other vehicles. during the distribution process special care has to be taken to ensure that the pellets do not suffer from continuous aberration only then will their nutritional value be maintained

Using the TCPEL 300-500kgs/h Flat Die Pellet Machine for pellet production

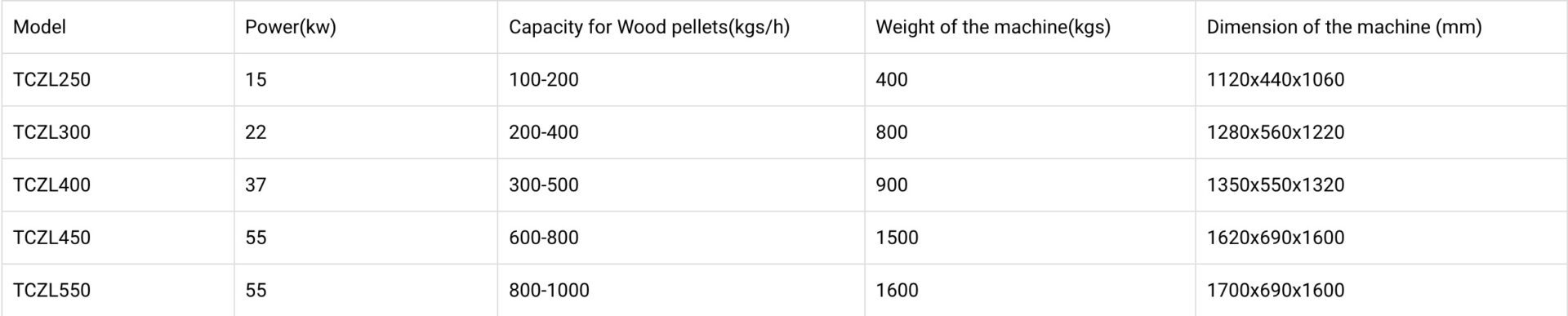

The flat die pellet machine from TCPEL is the most popular choice of pellet machine for preparing animal feed. This pellet machine has the capacity to produce around 300 to 500 kgs of animal feed per hour. This makes it a perfect choice of pellet machine for animal feed.

The machine can run with high power and can also reduce the wastage of raw material. It can also process a huge variety of raw materials.

So, whatever your choice of raw material may be, the TCPEL pellet-making machine is ideal for you. The machine is also suitable for both small-scale and large-scale use and comes with various advantages.

It has a central spindle quenching and tempering installation process. This allows stable operation of the machine. The device also has a lubricating oil pump which can automatically lubricate the main shaft and enhance the lifespan of the device.

The pellet-making machine has 100% pure copper wiring. This offers the required supply of power during the pelletizing process. The body of the pellet-making machine is also made up of highly durable material.

This allows you to keep using the machine for years without the need for regular repair and maintenance. You will also be able to acquire the maximum outcome from your efforts.

The TCPEL flat die pellet machine is already being used by multiple industries for pellet production because of its extraordinary capabilities. They are also being used to produce wood pellets of different shapes and sizes.

So, if you want to give your business an excellent boost and you also desire to produce animal feed pellets in high quantities and that too in the most convenient manner, then it is high time that you invest in the TCPEL flat die pellet-making machine.

Benefits of feed pellets

There are a lot of benefits associated with producing feed pellets. Some of the most important benefits have been mentioned for you:

High nutritional value: Now this is one of the major benefits of feed pellets. It comes with high nutritional value. The feed pellet has different types of organic materials in it which can add to its nutritional value.

You will also be able to adjust the nutritional value by altering the raw materials used for making the feed.

Easier transportation of the feed: Feed pellets can easily be transported from one location to another without any hindrance. This again adds to the convenience. Once the feed pellets are produced, they can be properly stored in containers and then they can be transported easily without the slightest trouble.

Long preservation time: Now here is another benefit of feed pellets. They have a long preservation time. You will be able to preserve the feed pellets quite easily. All you have to do is choose a cool and dry place for storage and you are good to go. The pellets will retain their original quality for years without you having to worry about the same.

Reduced waste: Feed pellets are a lot less prone to wastage and separation as compared to loose feed. Animals cannot easily choose their favorite components from the feed. This reduces the chances of selective feeding and the waste generation is also reduced. This again provides your business with a better ROI.

Improved digestibility: Feed pellets are produced under high temperatures and pressure. This makes them really easy to digest. Animals can easily extract the nutrients from the feed. This again makes them really suitable for enhancing the overall health of the animals. The animals will also not have to suffer from diseases related to digestibility.

Reduced contamination: There is a lot less chance of the pellets getting contaminated by any kind of harmful pathogen. This is mainly because of the fact that the pellets are exposed to high temperatures which kill the pathogen and other harmful bacteria from the feed. This again helps in improving the health condition. The nutritional value of the feed is also improved to a considerable extent.

Conclusion

So, as you can see, the entire process of preparing pellets from raw material is a time-consuming one. It also involves a lot of steps, each of which has to be carried out efficiently. You will also have to invest in the right pellet-making machine for yourself so that your business needs are fulfilled.

So, if you are looking for the best pellet-making machine that will fulfill your exact needs, then it is high time that you opt for the TCPEL pellet making machine.

The TCPEL pellet machine is indeed one of the most popular varieties of pellet-making machines available to us. It will help you to make maximum use of the available raw materials and will also fulfil your exact business goals and requirements. The machine can also be customized to suit your exact needs. So what are you waiting for?

Get in touch with the experts at TCPEL today and invest in the right machine for yourself. Contact us to know more about the range of products that we have got to offer to our customers.

Talk to An Expert

SHARE THIS POST

Talk to An Expert