10 Main Reasons Why Your Pellet Machine does not Discharge and Low Capacity

Why doesn’t the pellet machine discharge anymore?

What are the reasons why the pellet machine low capacity?

Let’s talk about these issues today: pellet machine troubleshooting.

Many customers who are making pellets for the first time will have various problems after purchase. For example, the biomass pellet machine cannot produce pellets, and the output capacity of the pellet machine only half of the stated capacity. Today, we will show you the 10 main reasons for these problems in the biomass pellet machine, hope this can help you.

Before you show you the reasons, let’s talk about how the wood pellet machine processing. The main reason why the biomass pellet machine can be shaped is that the friction between the pressing roller and the mold generates heat, so that the lignin in the wood chips can be completely released into a natural binder at a temperature of 80-90°, so that even without any adhesive the pellets can be shaped. After knowing this ,let’s talk about the main reason for the wood pellet problems :

First time use with new wood pellet machine ring die

The first time use, the wood pellet machine ring die hole has a poor finish. The drilling has burrs, so the friction of the discharge is large, which is easy to cause no discharge or less discharge, so it needs to be polishing and grinding. After mixing with sand, wood chips, and industrial waste machine oil, the sand is 30 %. Mix 60% wood chips and 10% oil to grind the biomass pellet machine.

Material accumulation in the pellet machine

After the pellet machine finish working, there will be some accumulations, and there will be no clean residue. After the next day the pellet machine continue working, due to the high temperature, it will solidify into a hard block, so the pellet machine cannot discharge normally. The solution is to clean the inside and clean up the residue.

Unstable working voltage

The motor of the wood pellet machine needs a certain voltage to operate normally. If the voltage is too low, even if the motor can roll, the power generated by it is not enough to quickly extrude the material in the compression chamber. At this time, there will be a lot of materials blocked in the compression cavity, affecting production.

Inappropriate distance between the wood pellet mill ring die and the pressure roller

After a period of production of the biomass pellet machine, due to the friction between the sawdust and the die press roller, the gap between the ring die and the press roller needs to be adjusted correctly. If the distance is too small, the press roller will increase the friction of the ring die and shorten the use time of the ring die. The assembly will cause the press roller to slip and unsmooth the discharge, which reduces the output; generally speaking, the gap between the ring die and the press roller is between 0.1 and 0.3mm. Normally, the new press roller and the new ring die are suitable Use a slightly larger gap. The old pressure roller and the old ring die should be matched with a smaller gap. The ring die with large aperture should use a slightly larger gap, and the ring die with small aperture should use a slightly smaller gap, which is easy to granulate. Large gaps should be used, and small gaps should be used for materials that are difficult to granulate. For the operator, it is necessary to have actual operating experience and be able to skillfully select and adjust the ring die gap.

Material moisture is inappropriate

For the biomass pellet machine, the raw material moisture is too high or too low will affect the quality of the pellets greatly. Too much or too little moisture in the material will cause the die hole to be blocked, causing the pellet machine to fail to discharge. Because the biomass pellet machine is elegantly shaped by physical pressing, its adhesiveness is formed by a combination of appropriate moisture and pressing, without any addition of chemical ingredients. Therefore, the moisture of the raw material is one of the important factors affecting the output of the biomass pellet machine. (It is recommended that the moisture of general raw materials should be controlled within 10-15%. If too wet, you need a sawdust dryer machine to remove the moisture .Of course, the specific situation still depends on the type of raw materials.

The ring die and the pressure roller are severely worn

The ring die and press roller are the main parts of the pellet machine, and they are also vulnerable parts. If the parts are aging or malfunction, these are also the reasons that the pellet machine will not discharge. If it is a newly purchased pellet machine, you only need to look at which part is not working to tell which is the problem. If it is a pellet machine that has been used for many years, it means that the parts are aging, just replace the parts.

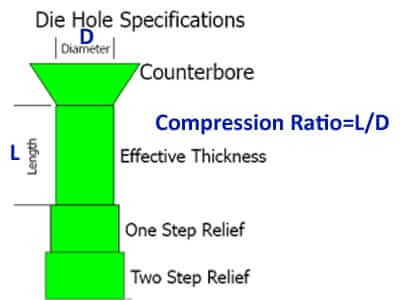

Inappropriate ring die compression ratio

The ring die compression ratio is incorrect. For a biomass pellet machine, compression ratio and moisture are two equally important factors. One of them is controlled by the raw materials and the other is controlled by the ring die. Both are indispensable. Otherwise, the output of the biomass pellet machine will be seriously affected. Therefore, before purchasing a biomass pellet machine, you must communicate with the manufacturer the compression ratio of the biomass pellet machine. Because different raw materials have different compression ratios, if you have multiple raw materials, you should communicate with the manufacturer to prepare a few more ring dies.

The material has high crude fiber content

Pellet machines have different models and powers. For different types of pellet machines, the requirements for pelleting are different. Some pellet machines are suitable for special pressing of coarse fibers, and some are suitable for special pressing of fine fibers. If your materials is too large, you need to use a fine hammer mill to reduce the size of your material. If you choose a small pellet machine to compress coarse fiber materials, it is also the reason why the pellet machine does not discharge. The solution is to communicate with the manufacturer and replace a pellet machine

Lack of Lubricating Oil

After long time working ,the pellet machine will need enough lubricating oil to for normal working ,if you don’t add enough oil ,the spare parts will easily wear out, and the wood pellets will not come out in good shape ,so every week ,the working staff should check the lubricating oil tank ,and add oil in time .

The ring die has been used for too long time and needs to be replaced

If the biomass pellet machine has been in normal production for a period of time and the output suddenly drops, then check whether the cone hole on the inner wall of the ring die is worn, whether the pressure roller is worn, and then check whether the ring die is out of round. Some inferior ring dies will have rough inner holes. The out-of-round ring die leads to unsmooth discharging, uneven particles, difficult discharging, and low output; it also causes the granulator to work weakly, the current is unstable, and the output is reduced.

Conclusion

Above are the 10 main reasons why the wood pellet machine can not discharge and low capacity . If you have any other questions, please contact us at any time, and we will provide customers with the most complete explanation and service.

Also Read:

How to Choose Biomass Materials for Pellet Production?

How to Maintain Your Pellet Machine?

How to Set Up a Pellet Machine?

Talk to An Expert

SHARE THIS POST

Talk to An Expert